Вавада казино зеркало - официальный сайт

Дата проверки зеркала:

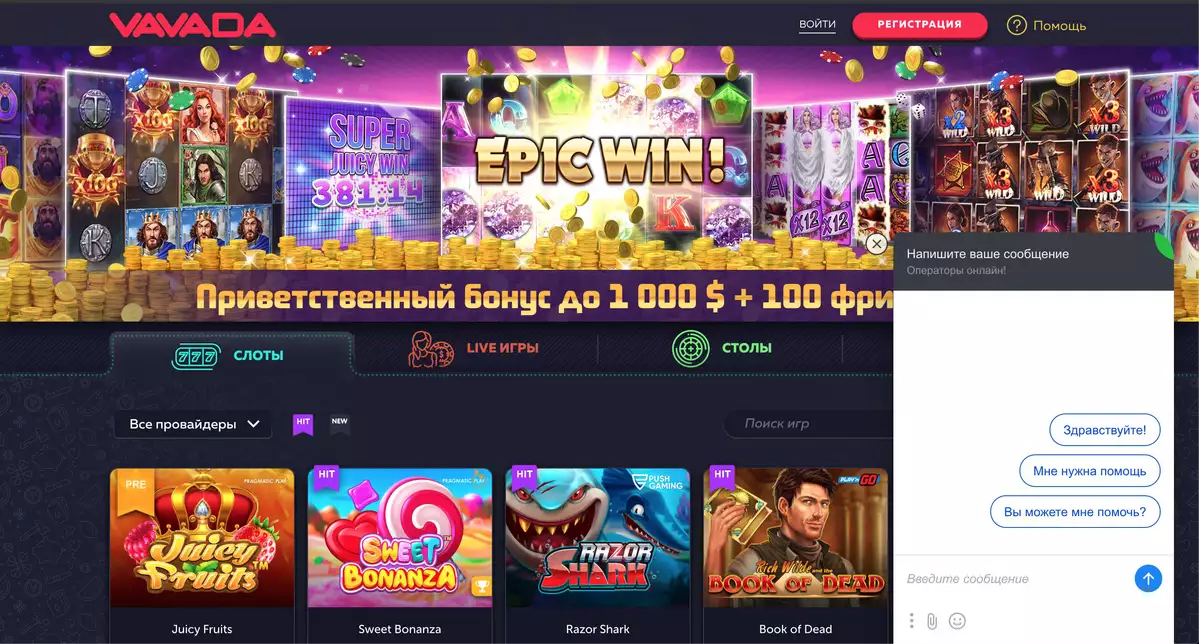

В осени 2017 года появилось популярное Vavada Casino, привлекающее азартных любителей. На его официальном сайте сразу привлекает внимание современный дизайн и удобная навигация. Надпись с названием казино на темно-фиолетовом фоне в верхней панели сразу бросается в глаза. Здесь же отображается ваш никнейм и кнопка для пополнения баланса.

В личном кабинете Vavada, доступном по клику на ваш никнейм, есть 5 вкладок:

- Профиль: Здесь можно настроить учетную запись, изменить пароль и пройти верификацию. Можно открыть дополнительные счета и отслеживать свой текущий ранг.

- Кошелек: Удобное управление финансами, отслеживание баланса и настройка платежных методов.

- Бонусы: Разнообразные предложения, повышающие шансы на победу и увеличивающие выигрыши.

- Статус: Отслеживание текущего статуса в казино и получение соответствующих привилегий.

- Сообщения: Связь с технической службой для решения вопросов или проблем

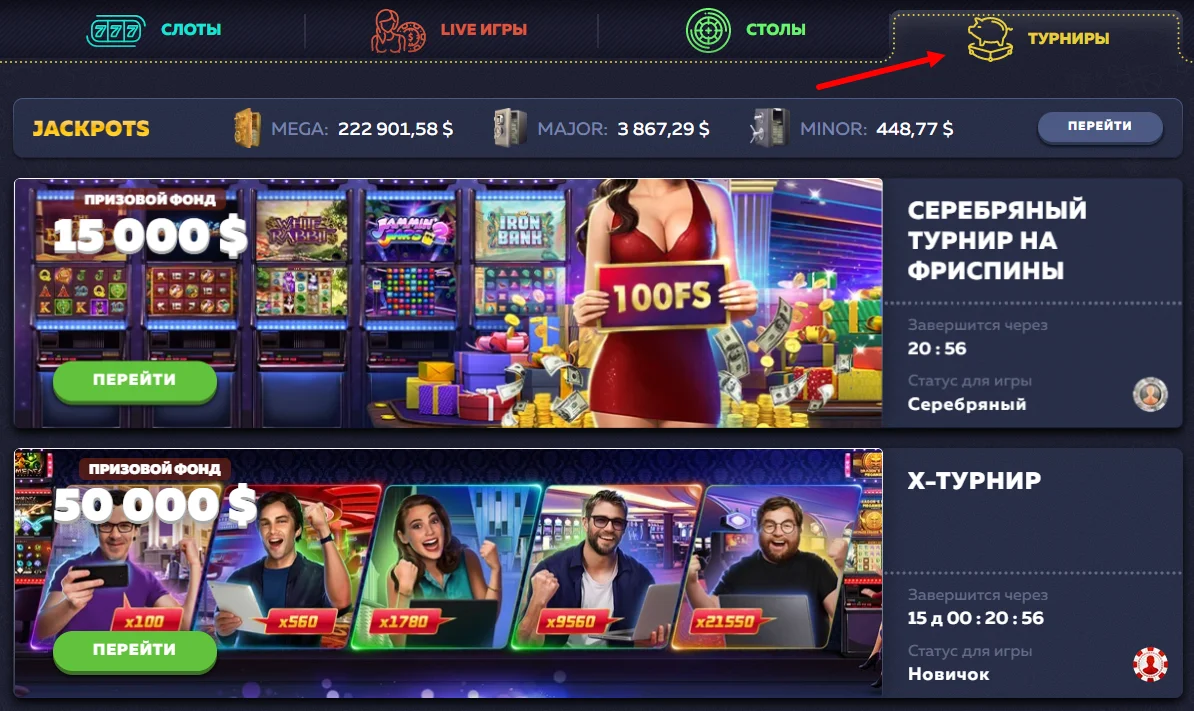

На сайте также есть баннер, приглашающий участвовать в турнирах и розыгрышах крупных призов, а также получить приветственный бонус.

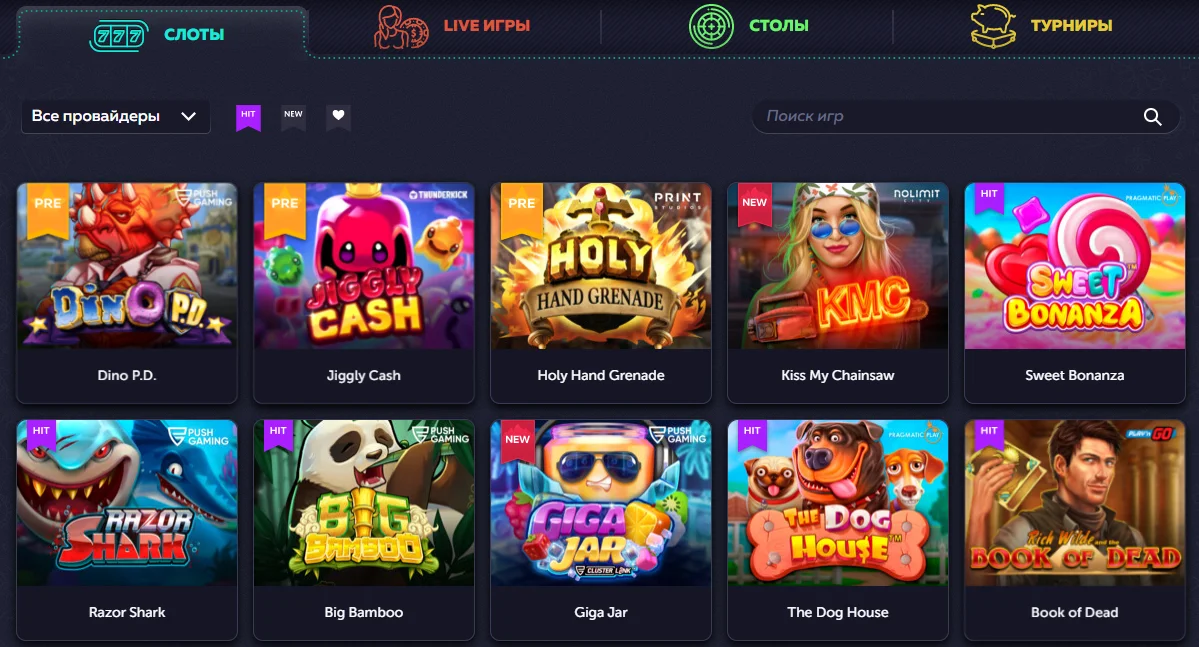

Затем можно ознакомиться с игровой коллекцией, выбрав категорию: Слоты, Столы, Live Casino или Турниры. Можно также посмотреть список популярных игр. В данный момент в топе находятся слоты, такие как Sweet Bonanza, Big Bamboo, The Dog House, Fruit Cocktail и Gates of Olympus.

Официальный сайт Vavada Casino сотрудничает с ведущими разработчиками программного обеспечения, такими как Amatic, BetSoft, Betgames, Microgaming, Blueprint, Slotmill, Red Tiger и Print Studios.

Полный список партнеров Vavada размещен в футере. Там также можно найти информацию о платежных методах, перейти и подписаться на социальные сети онлайн казино, а также ознакомиться с политикой сообщества и правилами ответственной игры.

Перед посещением официального сайта Vavada Casino игроки обратят внимание на его оформление и удобную навигацию. Казино представляет собой современное и яркое место, привлекающее внимание надписью с названием бренда в верхнем углу. Все элементы размещены на темно-фиолетовом фоне, что обеспечивает комфортный игровой процесс и упрощает управление.

Перед началом игры рекомендуется изучить информацию, размещенную в футере Vavada. Там можно найти ссылки на правила сообщества, полный список партнеров платежных систем, а также кнопки для быстрого перехода на страницы казино в социальных сетях. Подписка на все страницы казино позволит быть в курсе последних новостей и обновлений.

| 🕹️ Игровая платформа | Вавада |

| 🎯Дата открытия | 13.10.2017 |

| 🚩Лицензия | КLadyLuck88сао (№8048/JAZ) |

| 🎰 Топовые провайдеры | NetEnt, Igrosoft, Novomatic, Betsoft, EGT, Evolution Gaming, Thunderkick, Microgaming, Quickspin |

| 🃏Тип казино | Браузерная, мобильная, live-версии |

| 🍋Операционная система | Android, iOS, Windows |

| 💎Приветственные бонусы | 100 фриспинов + 100% к первому депозиту |

| ⚡Способы регистрации | Через email, телефон, соц. сети |

| 💲Игровые валюты | Рубли, евро, доллары, гривны |

| 💱Минимальная сумма депозита | 50 рублей |

| 💹Минимальная сумма выплаты | 1000 рублей |

| 💳Платёжные инструменты | Visa/MasterCard, SMS, Moneta.ru, Webmoney, Neteller, Skrill |

| 💸Поддерживаемый язык | Русский |

| ☝Круглосуточная служба поддержки | Email, live-чат, телефон |

Статьи по казино Вавада

Список:

- Обзор слота Dead or Alive на Вавада

Регистрация Вавада

Вавада казино приглашает вас зарегистрироваться и насладиться миром азартных развлечений. Создание аккаунта на платформе доступно для всех совершеннолетних пользователей, кто ранее не был зарегистрирован на данном домене. Проверка возраста осуществляется на каждом этапе взаимодействия с сайтом онлайн, включая заполнение анкеты новичка, получение персонального бонуса на День Рождения и вывод крупных сумм.

Мы принимаем безопасность нашей платформы во внимание и тщательно отслеживаем активность на странице. Пожалуйста, обратите внимание, что попытка участия с двумя профилями одновременно может привести к блокировке вашей учетной записи или аннулированию выигрыша.

Чтобы начать Vavada регистрацию онлайн, следуйте инструкции:

- Откройте официальный сайт Вавада казино с помощью браузера на вашем компьютере или мобильном устройстве.

- Нажмите на кнопку "Регистрация" и дождитесь загрузки анкеты.

- Заполните необходимые поля с вашими личными данными, такими как имя, фамилия и дата рождения.

- Выберите предпочитаемую валюту для игры из доступных вариантов: белорусские или российские рубли, гривны, канадские и американские доллары, тенге, евро, лиры или юани.

- Поставьте галочку, соглашаясь с правилами и политикой конфиденциальности.

Дополнительная авторизация с логином и паролем не требуется. Вы сразу окажетесь в своем профиле. В личном кабинете вам будет предложено подтвердить свой электронный адрес и, при желании, пройти верификацию. Верификация необязательна, но может значительно упростить процесс вывода средств и операции с валютой.

Если вы являетесь незарегистрированным посетителем, вы можете просматривать сайт и запустить демонстрационный режим. Однако, для выполнения операций со счетом и игры на риск необходимо пройти регистрацию. Процесс регистрации займет всего несколько минут. При заполнении анкеты вам потребуется указать следующие данные: имя, фамилию, электронный адрес и номер телефона, а также ваш день рождения. Выберите валюту для открытия счета из доступных вариантов. После заполнения всех полей, просто поставьте галочку, соглашаясь с правилами и политикой конфиденциальности.

Обратите внимание, что казино Вавада устанавливает определенные требования по возрасту и количеству учетных записей. Участие в азартных развлечениях разрешено только лицам, достигшим 18 лет, и служба безопасности тщательно следит за соблюдением этих правил. При выявлении нарушений функции аккаунта могут быть временно ограничены, а повторные нарушения могут привести к безвозвратному блокированию учетной записи.

Создание нового аккаунта Vavada разрешено всем совершеннолетним посетителям, которые ранее не регистрировались в онлайн казино. Мультиаккаунты строго запрещены, поэтому, если у вас уже есть аккаунт, рекомендуется восстановить доступ к нему, а не создавать новый профиль. Перед регистрацией в казино Вавада рекомендуется ознакомиться с правилами ответственной игры и понимать, что средства, потраченные на ставки, не подлежат возврату. Вы несете полную ответственность за свои действия в своем профиле.

Есть возможность зарегистрироваться на Вавада казино через мобильную версию сайта, просто откройте официальный сайт с помощью своего смартфона или планшета. Все удобства и возможности нашего казино доступны вам в любое время и в любом месте.

Регистрация и Личный кабинет ВавадаРабочие зеркала сайта Vavada com

Список запасных ресурсов всегда имеется у наших сотрудников поддержки. Чтобы получить полный перечень ссылок, просто свяжитесь с ними в чате. Они будут рады помочь вам.

Кроме того, информацией о зеркалах располагают и наши менеджеры социальных сетей. Не забудьте подписаться на нас в Instagram, Telegram и Вконтакте, чтобы всегда быть в курсе последних обновлений и узнавать о доступных зеркалах.

Если вы предпочитаете другой способ поиска зеркал Vavada, то обратите внимание на форумы, посвященные азартным заведениям. Там гемблеры со всех площадок обсуждают актуальные проблемы и делятся решениями. Однако будьте осторожны, на таких форумах могут быть мошенники. Проверяйте все ссылки у официальных представителей игрового зала перед переходом, чтобы защитить свои личные данные.

Вавада онлайн казино периодически может быть заблокировано в странах СНГ из-за действий Роскомнадзора. Однако разработчики всегда создают рабочие зеркала, чтобы вы могли продолжать наслаждаться игрой. Эти зеркала являются альтернативными доменами с измененными адресами. Внешний вид и навигация на них аналогичны официальному сайту, и вы не будете ограничены в своих действиях, включая регистрацию, пополнение счета, активацию бонусов и общение с нашей технической поддержкой.

Чтобы найти актуальное зеркало Вавада, есть несколько способов:

- Обратиться к нашей технической поддержке в чате.

- Связаться с нашими менеджерами в социальных сетях.

- Посетить тематические форумы, где обсуждаются азартные заведения.

Однако помните, что при самостоятельном поиске на сторонних площадках могут быть мошенники. Поэтому будьте внимательны и проверяйте все ссылки у официальных представителей Vavada.

Если вам нужно получить рабочее зеркало немедленно, самый быстрый способ - написать оператору в чате поддержки. Они ответят вам в течение 3-5 минут и предоставят актуальный список всех доменов на сегодня.

Вход на зеркало Вавада:

- Перейдите по найденной ссылке.

- Введите свой логин и пароль в поле авторизации.

- Дождитесь загрузки профиля.

- Запустите любой автомат и наслаждайтесь игрой.

После входа все ваши данные автоматически синхронизируются, в личном кабинете отображается история транзакций с момента регистрации, текущий ранг и неиспользованные бонусы.

Запасные сайты Вавада создаются регулярно, и мы уведомляем об этом через электронную почту и социальные сети. Однако, если вас застала блокировка врасплох, можете самостоятельно найти рабочее зеркало. Для входа на зеркало просто перейдите по ссылке, нажмите кнопку авторизации и введите логин и пароль от своего профиля.

Все рабочие зеркала Вавада полностью идентичны официальному сайту и предоставляют те же функции и возможности. Единственное отличие - измененный домен. При использовании зеркала вам доступен личный кабинет, активация бонусов, денежные переводы, управление кошельками, общение с поддержкой и администрацией.

Если вам нужно получить актуальное рабочее зеркало Вавада на сегодня, рекомендуем обратиться в круглосуточный чат поддержки, где оператор предоставит вам полный список рабочих доменов. Сохраните их на будущее в закладках или заметках, чтобы всегда быть в курсе доступных зеркал.

Список рабочих зеркал Вавада

Турниры, слоты и live games на Вавада

Вавада казино предлагает разные игры, чтобы удовлетворить все ваши азартные потребности.

В категории "Слоты" вы найдете развлечения с простыми правилами и классической механикой. От "Cyber Wolf" и "Rise of Merlin" до "Slotomoji" и "Sakura Fortune", здесь каждый найдет подходящую игру.

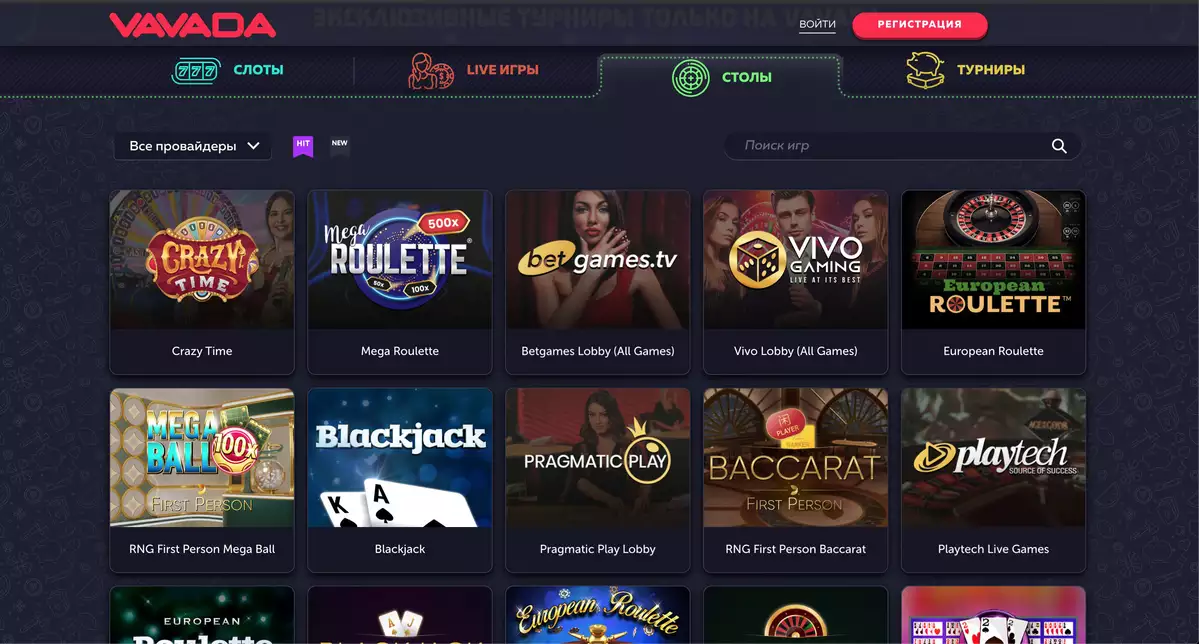

Если вы предпочитаете настольные игры, то обратите внимание на раздел "Столы". Он предлагает разнообразные настолки от первого лица, такие как "Aviator", "Fruit Towers", "Space XY", "Spaceman" и "Easter Plinko". Здесь вы сможете насладиться разными жанрами и испытать удовольствие от классических игр.

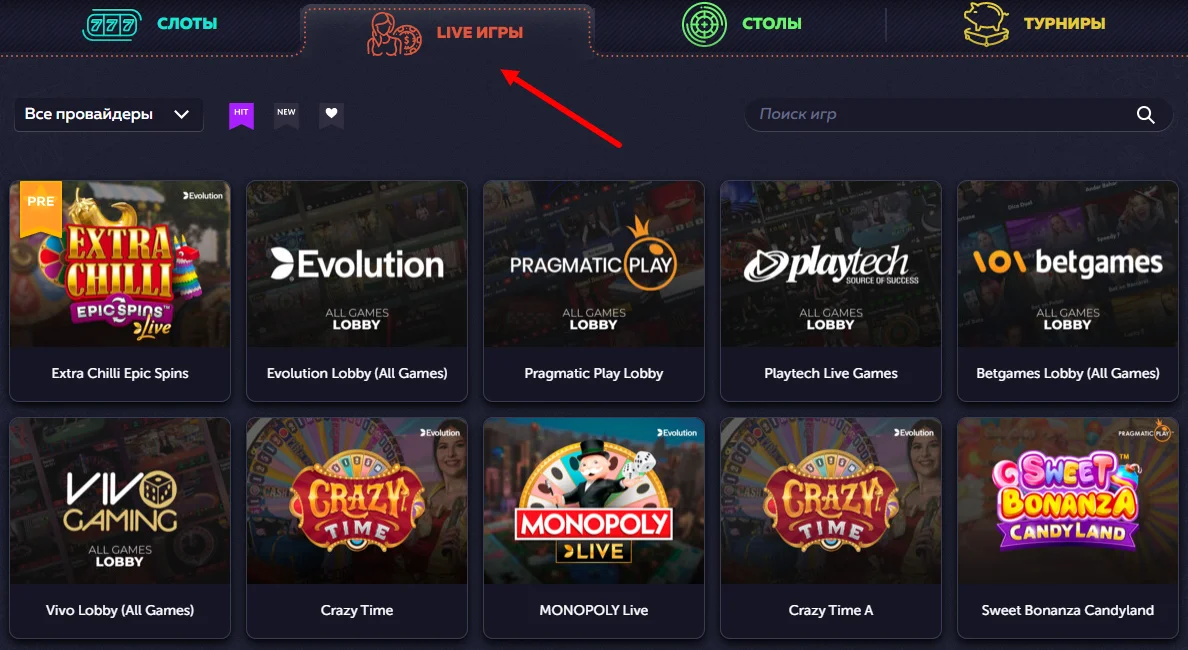

Живые дилеры - это раздел, в котором находятся онлайн-симуляторы с настоящими ведущими в красивой атмосфере. Игры, такие как "Crazy Time", "Extra Chilli Epic Spins", "Dream Catcher" и "Crazy Coin Flip", оживят ваше игровое время и добавят аутентичности вашему опыту.

Для тех, кто любит состязания и жаждет крупных призов, на Вавада казино доступны турниры. Новички, золотые, серебряные и платиновые игроки соревнуются за призы в различных турнирах, включая Х-турнир, на кэш и на фриспины. Эти состязания организованы с учетом уровня программы лояльности и требуют выполнения определенных условий для участия.

Библиотека на Вавада казино представлена лицензированными провайдерами, которые гарантируют честность и качество своих разработок. Более 50 компаний, таких как Betgames, Amatic, Betsoft, Blueprint, EGT, Elk Studios, Endorphina, Evolution, Tom Horn, TrueLab Games, VIVO, Yggdrasil, Igrosoft, BGaming, Big Time, Eurasian Gaming, Pocket Games Soft и другие, предлагают свои игры на площадке.

Перед началом игры рекомендуется ознакомиться с правилами и особенностями каждой игры, а также с ответственными игровыми практиками и требованиями казино. Помните, что азартные игры должны быть воспринимаемы как развлечение, а не способ заработка крупных сумм.

Лучшие слоты на Вавада

| 🔥 Бездепозитный бонус: | 100 фриспинов |

| 💻 Официальный сайт: | vavada.com |

| 🎲 Тип казино: | Слоты, Столы, Live, Турниры |

| 🗓 Рабочее зеркало: | Есть |

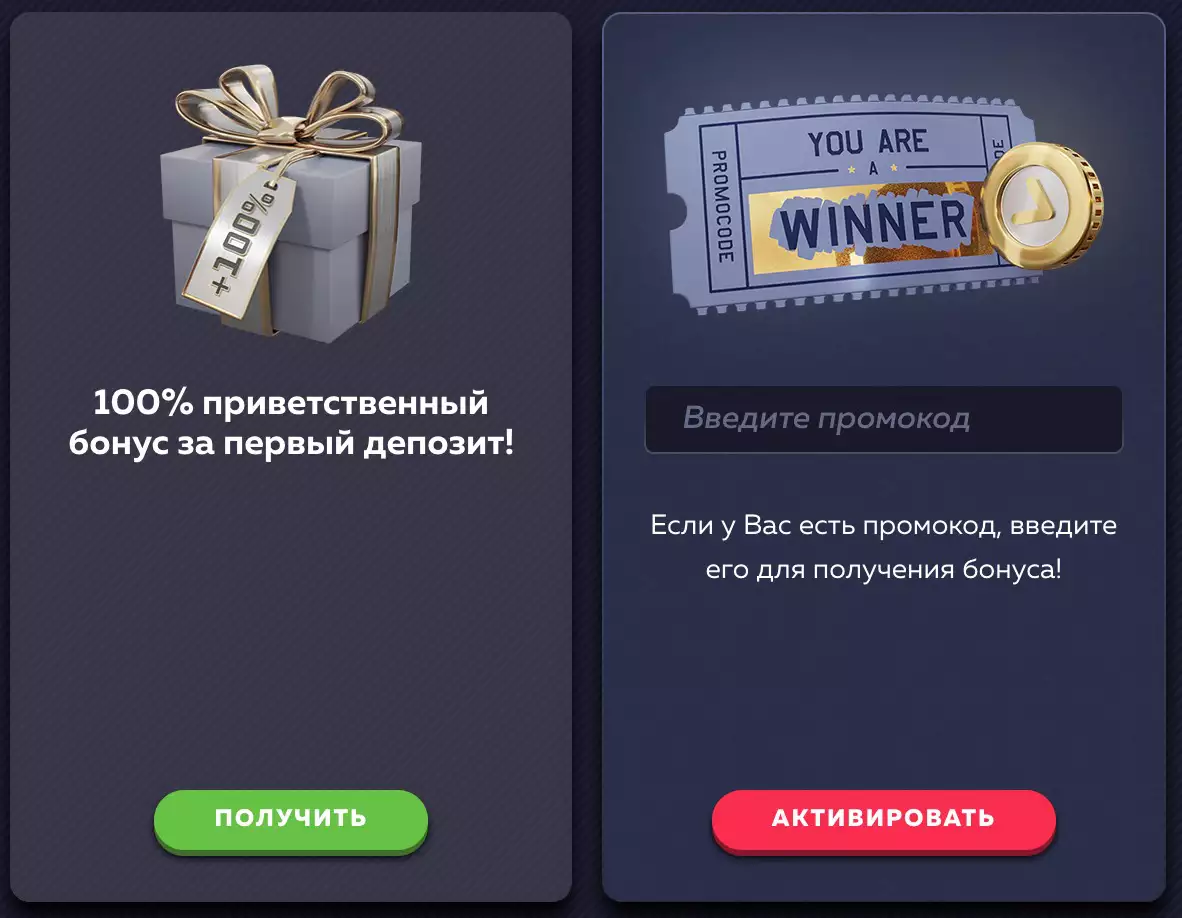

Вавада бонусы

Бонусы и промокоды на Вавада казино привлекают новых и опытных игроков. Программа лояльности предлагает разнообразные вознаграждения и персональные предложения.

После регистрации Vavada, новым игрокам предоставляется приветственный пакет. Он включает 100 бесплатных вращений в игре Great Pigsby Megaways. Бонус активируется в течение 14 дней и имеет вейджер х25. Также, при пополнении от 50 до 60 000 рублей одним платежом, игроки получают удвоение своего депозита. Для вывода выигрыша требуется выполнить вейджер х35.

Активным игрокам, которые провели более месяца на сайте и показали отрицательную статистику, предлагается кэшбэк в размере 10% от потраченных средств. Коэффициент отыгрыша составляет х5.

Дополнительные бонусы можно получить с помощью промокодов. Они выдаются за активность, участие в акциях, пополнения и креативность в розыгрышах в социальных сетях казино. Также, в День Рождения игрокам предоставляются индивидуальные промокоды.

Для получения подарков и промокодов, игрокам рекомендуется обратиться в службу поддержки Vavada.

Используйте ссылку для загрузки приложения Vavada, чтобы получить доступ к эксклюзивным промоакциям и дополнительным поощрениям.

Поддержка Vavada казино

Служба поддержки Vavada казино работает 24/7. Мы ценим каждого клиента и стремимся предоставить высококачественное обслуживание. У нас работают настоящие специалисты, которые ответят на ваши вопросы и помогут решить любые проблемы.

Для начала диалога с нами достаточно кликнуть на значок вопроса на сайте Vavada. Вы сразу же будете подключены к живому оператору, который ответит на ваш запрос в течение 5-15 минут. Мы гарантируем, что разговор не завершится, пока ваша проблема полностью не будет решена. Наша оперативность и качество обслуживания получают много положительных отзывов от клиентов.

У нас есть несколько способов связи. Можете воспользоваться удобным онлайн-чатом, который открывается при нажатии на значок вопроса вверху страницы. Мы также доступны по электронной почте [email protected]. Если вы предпочитаете видео-общение, добавьте нас в Skype по адресу live:.cid.1f81fca32d3af0a6. Также можно позвонить по номеру +1 404 382 0303.

Выберите удобный для вас способ связи, и наша служба поддержки Vavada окажет вам качественную и индивидуальную помощь. Мы всегда готовы решить любые ваши вопросы и обеспечить приятное игровое впечатление.

Официальный сайт Вавада казиноЧасто задаваемые вопросы

Как вывести деньги с вавада

Чтобы вывести деньги с Вавада, зайдите в свой аккаунт, выберите раздел кассы и найдите опцию "Вывод средств". Укажите необходимую сумму и предпочитаемый метод вывода, следуя инструкциям на экране.

Вавада казино посмотреть как играют

Чтобы посмотреть как играют в Вавада казино, зайдите на официальный сайт или посетите стримы и видеозаписи игроков на платформах стриминга. Там можно наблюдать разные игры и стратегии игроков.

Как выиграть в казино вавада

В казино Вавада выиграть зависит от везения и случая. Однако, можно повысить свои шансы, выбирая игры с высоким процентом выплат, устанавливая разумные лимиты ставок и играя ответственно.

vavada казино как отыграть бонус

Для отыгрыша бонуса в Vavada казино, обратитесь к условиям акции. Обычно требуется сделать определенное количество ставок на игры, учитываемые в отыгрыше. Следуйте правилам вейджера, указанным в условиях акции, чтобы сделать бонус выводимым.

Отзывы Vavada

-

Vavada казино - мое любимое место для игры! Огромный выбор слотов, быстрые выплаты и отличная бонусная программа. Рекомендую!

-

Я уже несколько лет играю в Вавада казино и никогда не разочаровывался. Высокое качество игр, приветливая поддержка и удобный интерфейс.

-

Вавада казино - настоящий рай для казино-энтузиастов. Большие выигрыши, быстрые выплаты и надежная защита данных. Просто отлично!

-

Очарована Вавада казино! Играю на своем смартфоне, и это настоящее удовольствие. Интуитивно понятный интерфейс и качественный игровой опыт.

-

Вавада казино - это мое счастливое место! Здесь я выиграл несколько крупных джекпотов. Быстрые выплаты и отличная поддержка. Всем советую!